Formabar™

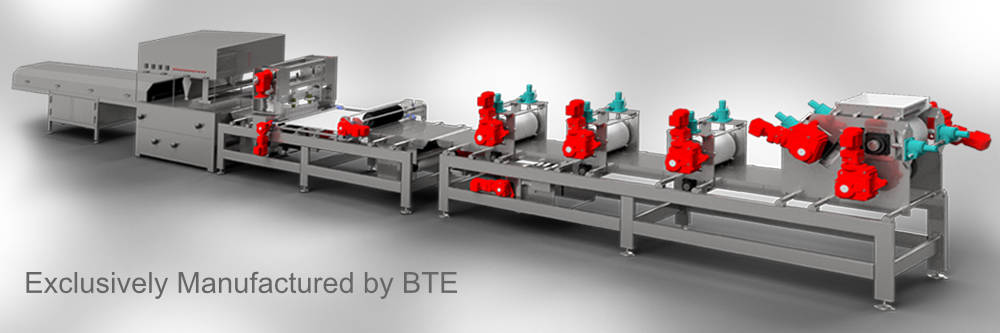

We at BTE are very proud to introduce you to our most innovative product line for the production of Health and Snack Bars – FORMABAR™. If you’re in the business of making any kind of snack or health bars, you’re going to want to take a very close look at the all new BTE exclusive FORMABAR™ system. Our registered and trademarked FORMABAR™ product is a complete bar making line that contains every component you’ll need in order to make the highest quality bars as efficiently, quickly, and cost-effectively as possible. Every component in this system has been developed from the ground up for long-lasting quality and efficiency. FORMABAR™ not only produces snack and health bars, but it’s a versatile and complete bar production line that’s capable of producing cereal, nutritional, protein, fruit & nut bars, and just about any type of bars that are being currently being sold in markets around the world today..

We at BTE are very proud to introduce you to our most innovative product line for the production of Health and Snack Bars – FORMABAR™. If you’re in the business of making any kind of snack or health bars, you’re going to want to take a very close look at the all new BTE exclusive FORMABAR™ system. Our registered and trademarked FORMABAR™ product is a complete bar making line that contains every component you’ll need in order to make the highest quality bars as efficiently, quickly, and cost-effectively as possible. Every component in this system has been developed from the ground up for long-lasting quality and efficiency. FORMABAR™ not only produces snack and health bars, but it’s a versatile and complete bar production line that’s capable of producing cereal, nutritional, protein, fruit & nut bars, and just about any type of bars that are being currently being sold in markets around the world today..

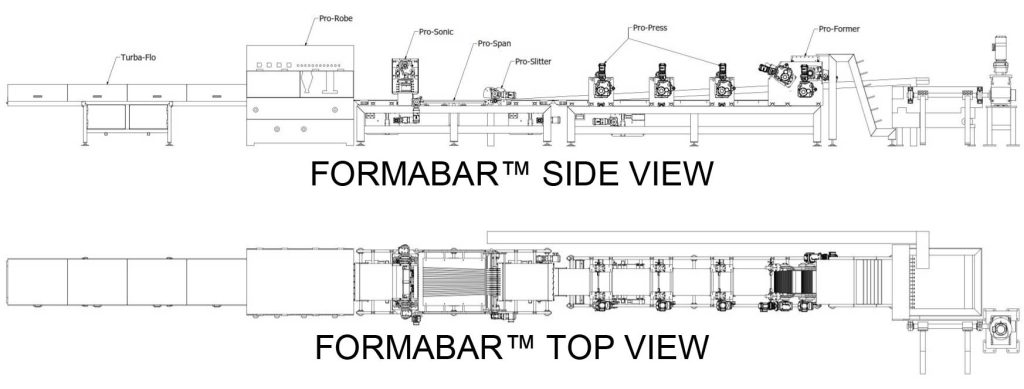

FORMABAR™ is made up of 7 vital components:

Pro-Former™: The Pro-Former™ heads the line by creating a workable slab of product. (The 3-roll option adds improved weight consistency.) The unique design allows this component to reduce loss and improve the yield of the final product. (Each Pro-Former™ is delivered with custom milled grooves depending on client’s product requirements.) Increased efficiency in speed and energy savings over earlier methods of forming have been achieved while at the same time reducing re-works. The Pro-Former™ also reduces need for additional ancillary equipment, such as water chillers, when handling extremely sticky or tacky product.

Pro-Press®: The Pro-Press™ sizes the product slab. It has been specially designed to improve line speed and product efficiency with high-speed continuous slab production. This press offers a 2 or 3-Roller Pro-Press™ attachment. There is also an optional driven Backer Roll.

Pro-Slit®: The Pro-Slit™ system separates the product slab into strips. It incorporates a unique, self-lubricating, slitting system as an option. The built in self-lubricating feature has been designed to extend the life of the cutting blades by extending the life of the blades. A better looking final product is produced, product loss is minimized, and maintenance and blade replacement costs are reduced.

The Pro-Slit™ system, the Pro-Span™ and Pro-Sonic™ all offer the following features and options:

- Optimized Spacing for Slitting, Spreading, and Cutting to feed automation systems for different packaging configurations.

- Optional Individual or Expanding Spreader Belt

- Optional Ultrasonic Guillotine Attachments

Pro-Span™: The Pro-Span™ spaces product appropriately for the rest of the automation process.

Pro-Sonic™: The Pro-Sonic™ cuts strips that have come out of the The Pro-Slit™ system into the final bar shapes. This step prepares the product for enrobing and/or packaging.

Pro-Robe™: Our Pro-Robe™ enrobes or coats the formed, pressed, and cut bars with the final coatings, such as chocolate, or white confectionery coatings for snack bars; or yogurt, carob, fruit flavors, or other healthy coatings for protein bars and health bars.

Turba-Flo™: The Turba-Flo™ sets the coating around bars by cooling the bars to the necessary temperature as quickly as possible. This step also stops decorative swirls and stripes from melting or getting smeared in subsequent steps such as packaging.

FORMABAR™ at a Glance:

| Machine | Purpose |

|---|---|

| Pro-Former™ | Creates Workable Slab of Product |

| Pro-Press™ | Sizes the Product Slab |

| Pro-Slit™ | Separates Product Slab Into Strips |

| Pro-Span™ | Spaces Product Appropriately for the Automation Process |

| Pro-Sonic™ | Cuts Strips into Bars |

| Pro-Robe™ | Enrobes Bars with Different Coatings |

| Turba-Flo™ | Sets Coating Around Bars |

Commercial and Industrial

Health Bar & Snack Bar Equipment Manufacturer

FORMABAR™ was designed with your company’s needs in mind. We’ve developed each component to be trouble-free, and cost-efficient. We’ve also made each machine in the line work properly and efficiently with every other machine on the line, to give years of superior and trouble-free production capabilities. If you’re considering producing health or snack bars, or considering updating your older inefficient equipment, there’s never been a better time to do so than right now with the all new FORMABAR™.

We think, as a BTE customer, you shouldn’t just make bars. We want to help you make outstanding bars that customers and consumers will love, and buy again and again. And, we want you to make them as efficiently and cost effectively as possible. As a manufacturer of health bar and snack bar equipment for commercial and industrial production, with years of experience building production lines for small, medium, and large producers, we welcome your inquiries, and look forward to working with you. Please feel free to get in touch with us to find out more.